Introduction

In a context where environmental and industrial challenges require ever more efficient water treatment solutions, membrane technologies occupy a central place. Widely used in many industrial sectors, particularly for water treatment, membranes make it possible to separate the constituents of a fluid, depending on their size or nature. Ceramic membranes are distinguished by their robustness, durability and separation efficiency, providing a reliable alternative in extreme conditions.

Membrane filtration

Pressure driven membrane processes make it possible to achieve a liquid-solid separation, using the pressure difference as the motor.

Porous membranes allow compounds to be separated according to their size: the filtrate is made up of all the compounds small enough to pass through the pores while the species that are too large are retained on the membrane, thus constituting the permeate. This separation can be used for the purpose of concentration and purification of microscopic components.

Porous membranes can be classified according to the size of their pores, corresponding to a cut-off threshold expressed in Dalton (1Da = 1g/mol).

Filtration Type | Pore Diameter | Usage |

Microfiltration | 0.1 to 10 μm | Removing suspended particles, bacteria |

Ultrafiltration | 2 to 100 nm | Retaining macromolecules: polymers, proteins, colloids |

Nanofiltration | 0.5 to 2 nm | Retain multivalent ions |

There are also dense (non-porous) membranes, such as those used to achieve reverse osmosis. In this case, it is the phenomenon of diffusion through the semi-permeable material that allows the separation of the compounds. The pressure makes it possible to control the difference in concentration between the two sides of the membrane, and therefore the direction of diffusion.

Several types of membranes can be involved in baromembrane processes: organic, polymer-based, and ceramic (or inorganic) membranes.

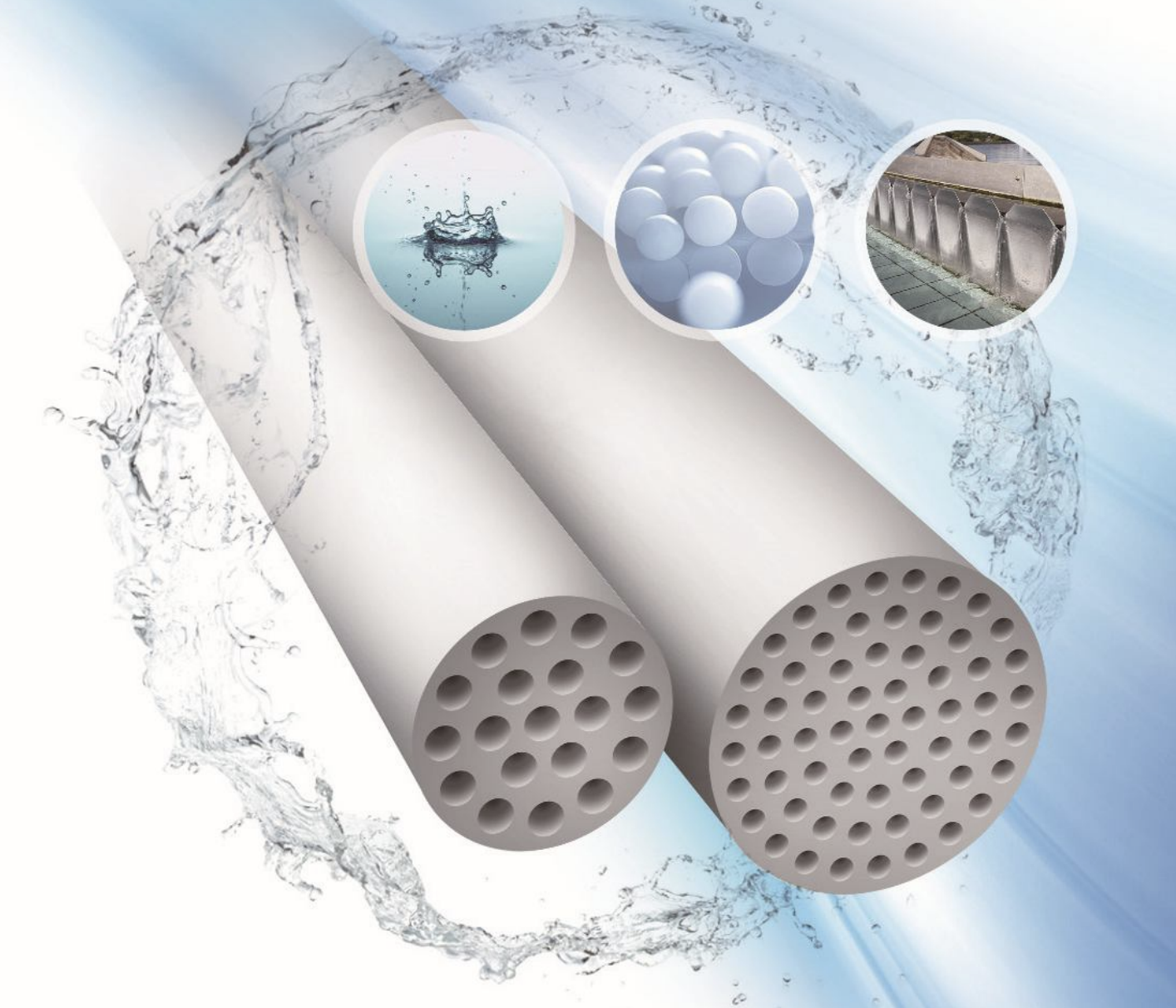

Ceramic membranes

Ceramic membranes are distinguished by their specific properties. Metal oxides have specific physical and chemical properties, and are therefore the materials of choice for the manufacture of membranes. Alumina (Al2O3) is commonly used because it has good chemical and thermal stability. Titanium (TiO2) is the ceramic material with the best chemical resistance, while Zirconia (ZrO2) has mechanical and hydrophilic properties.

Porous ceramic membranes typically have a layered structure. First, there is a macroporous layer, which serves as a mechanical support, an intermediate layer, whose role is to bind the coating to the support. The filtration layer, whose pores have the required diameter, allows the separation to be achieved. The choice of materials used for each layer depends on their properties.

Structure typique d’une membrane céramique (Source : Duscher, S. (2013). Ceramic membranes in chemical and pharmaceutical applications. Ceramic Applications, 1(1):19–23)

Pros and Cons

Membranes are more widely used in industry, especially because of their low cost. However, even though ceramic membranes are more expensive due to the cost of raw materials and the cost of production, they are able to withstand extreme conditions in terms of temperature, pressure, and exposure to chemicals.

Critères | Organic Membranes | Ceramic Membranes |

Durability and Longevity | Limited lifespan (months to a few years) | Very long lifespan (years to decade) |

Chemical Resistance and Temperature | Sensitive to harsh chemicals and high temperatures | Excellent resistance to chemicals and high temperatures |

Filtration Performance | Good performance but prone to clogging | Highly efficient separation and less prone to clogging |

Costs | Low initial cost but high long-term replacement and maintenance costs | Often higher upfront cost but lower maintenance costs in the long run |

Specific Applications | Drinking water, food and pharmaceutical industries | Wastewater treatment, harsh industrial environments |

Cleaning and Maintenance | Gentle and frequent chemical cleaning | Aggressive cleaning (mechanical and chemical) possible |

Reduction of Biofouling | More susceptible to biofouling | Significant reduction in biofouling due to smooth surface |

Some applications of ceramic membranes

Ceramic membranes, especially for microfiltration and ultrafiltration, have varied applications in wastewater treatment due to their robustness, separation performance and long service life. Their effectiveness is verified in various industrial contexts.

1. Vehicle washing wastewater treatment

The water from car washing is loaded with anionic surfactants, and can also contain sediment and other impurities, especially during periods of rain or snow. The use of ceramic membranes allows these contaminants to be effectively removed, in order to reuse the treated water.

This technology is distinguished by a significant reduction in turbidity (from 10 to 0.2 NTU), and operational stability, with monthly cleaning being sufficient. In comparison, hollow fiber polymer membranes require more frequent cleaning (every 3 to 5 days), offer lower flow rates (up to 3 times less), and have a shorter lifespan, which underlines the interest of ceramic membranes in this field.

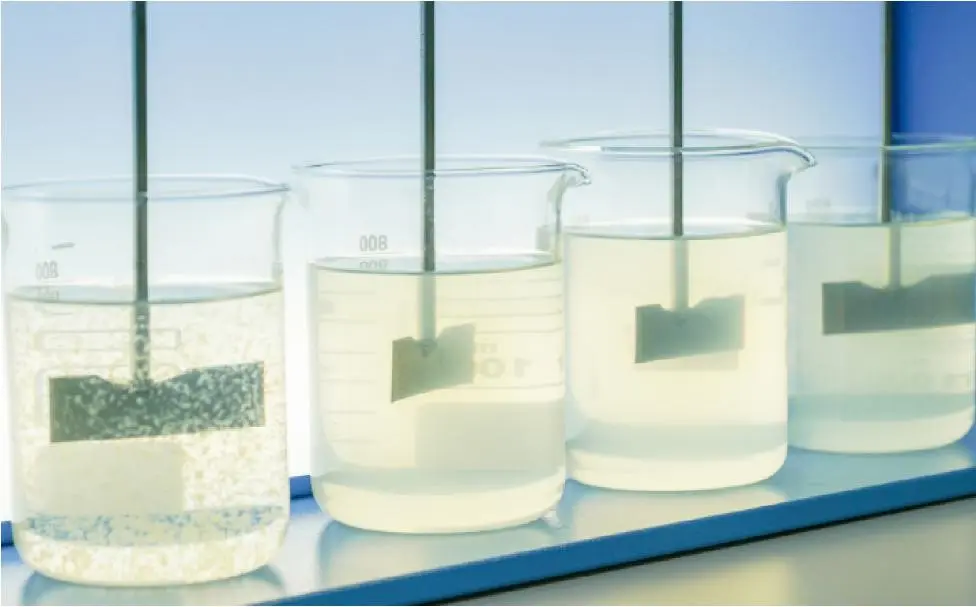

From left to right: Filtrate and concentrate.

2. Treatment of flue gas scrubbing water

Incineration plants generate gaseous discharges, which are subject to strict regulations and must be treated to comply with regulations. Wet processing allows the capture of compounds contained in the gas phase by liquids. This liquid by-product, called fume scrubbing water, contains chloride, heavy metals and other toxic substances that are prohibited from being discharged, and therefore must be treated.

After pre-treatment, ceramic membranes remove suspended particles and ensure a clear filtrate (turbidity reduced from 200 to less than 1). Filtration helps ensure the stability of downstream processes and improves overall processing efficiency. Proper treatment can allow the recovery of salts contained in the water, and its reuse after a purification step.

From left to right: Untreated water, filtrate and concentrate.

3. Kitchen Wastewater Treatment

Kitchen wastewater is particularly loaded with BOD (biological oxygen demand), COD (chemical oxygen demand), oils and fats. They degrade quickly and generate unpleasant odors. Ceramic membranes allow for the removal of suspended solids and conditioning the water for subsequent purification and concentration steps. Some extracted substances can even be used as resources.

From left to right: Filtrate and untreated water.

Conclusion

Ceramic membranes are a robust and high-performance filtration solution, particularly suitable for demanding industrial environments. Their long service life, resistance to extreme conditions (temperature, chemicals) and separation efficiency make them high-performance and durable tools. However, their use is not universal: the choice between organic membrane and ceramic will always depend on the context of application, economic constraints and treatment objectives.

Sources:

BERLAND, J.M. and JUERY, C. (2002) ‘Membrane Processes for Water Treatment’.

Hoyos Velasquez, A.M. (2025) Performance of a washing column with respect to incineration flue gas particles: experimental study in an incineration plant. Process engineering. École nationale supérieure Mines-Télécom Atlantique.

Li, J. (2018) Atomic Layer Deposition for Synthesis of Ceramic Tight UF Membrane. Delft University of Technology.

Samhari, O. (2021) Graphene oxide-modified ceramic membranes and polymers for the retention of organic molecules and the desalination of brackish water and seawater. University of Rennes, University of Hassan.