OSEIDO designs, manufactures and commissions industrial and pilot plants of all sizes. Our treatment units are tailor-made, adapted to each project and customer’s specificities.

We adapt membrane technologies to the constraints of your process and to your technical environment. We operate in many sectors of activity such as the chemical, metallurgical, mechanical & automotive, food & beverage, textile, and irrigation industries, etc… which enables us to master and offer a wide range of technologies and components.

A physical separation process is used to purify, concentrate or fractionate molecules dissolved or suspended in water.

Under the effect of pressure, molecules smaller than the membrane’s cut-off threshold pass through the membrane’s pores and larger molecules are retained.

Filtration techniques vary according to the cut-off / rejection threshold of the membrane.

It makes it possible to characterize the effluents to be treated, collect the input data, define the needs in order to define the treatment/depollution objectives and propose the appropriate treatment.

A laboratory test is used to verify the pollution control performance of the proposed treatment process.

This stage defines the technical and financial sizing of the installation.

If required, we install a pilot on site to validate the conclusions of the tests and to validate the solution to be implemented.

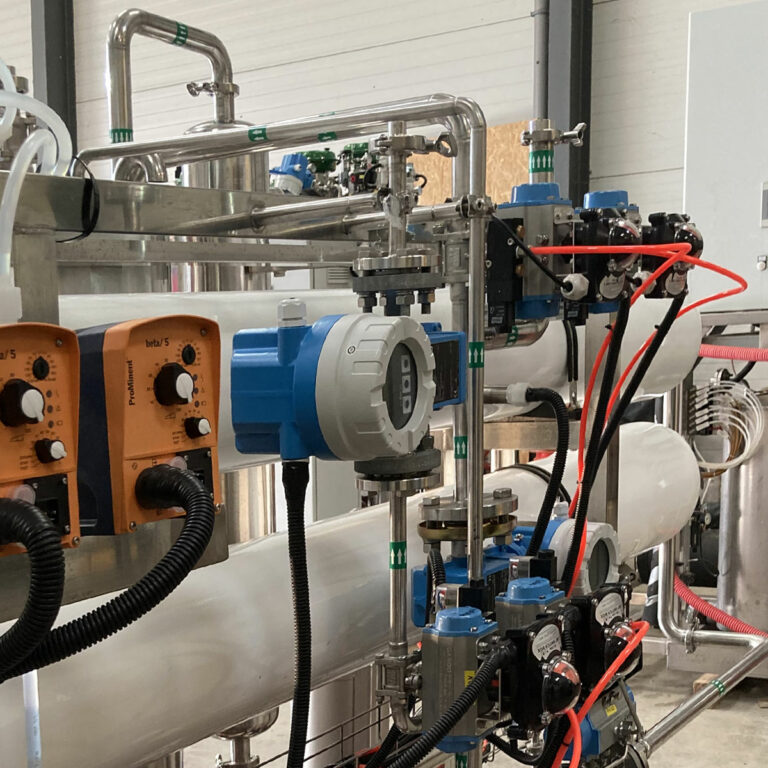

Our in-house engineering department designs and builds the skid. It is then assembled by our partner.

We manage and carry out all the checks and tests prior to delivery to site.

The installation is delivered, interconnected, and commissioned with our teams. Water tests and then tests with the effluent to be treated complete the commissioning stage of the unit. We provide start-up assistance and operator training on site.

We will accompany you in the optimization of your installations, ensure maintenance, replacement of parts (new membranes and various spare parts for instrumentation, mechanical parts, consumables…) and train your operators.

Your water and bio-waste treatment issues are unique.

Our solutions are tailor-made.OSEIDO